BLOG ENTRY - 16 FABRICATION, ERECTION &HYBRID STRUCTURES

FABRICATION, ERECTION & HYBRID STRUCTURES

Hello guys!

We are going to take a look at the fabrication and erection processes of steel construction and hybrid structures.

Fabrication process:

Fabrication is the process used to manufacture steelwork components that will when assembled and joined forms a complete frame.

Structural steel fabrication can be carried out in a shop or at the construction site. Fabrication carried out in shops is precise and of assured quality whereas fabrication in the construction site is comparatively inferior in quality.

Sequence of activities in fabricating shops:

1. Surface cleaning

2. Cutting and Machining

3. Punching and Drilling

4. Straightening, bending and rolling

5. Fitting and reaming

6. Fastening (Bolting, riveting and welding)

7. Finishing

8. Quality control

9. Surface treatment

10. Transportation

Issues in Fabrication process:

- External damage to materials

- Immediate Spring back after fabricating

- Price volatility of raw materials

- Unavailability of steel fabricators

- Problems with fabricating equipment

Erection process:

Erection of steel structures is the process by which the fabricated structural members are assembled together to form the skeletal structure. This process is normal carried out by the erection contractor. Cranes and MEWPs (Mobile Elevating Work Platforms ) are mainly used.

Sequence of activities during erection:

1. Receiving material from the shop and temporarily stacking them, if necessary.

2. Lifting and placing the member and temporarily holding in place.

3. Temporarily bracing the system to ensure stability during erection.

4. Aligning and permanently connecting the members by bolting or welding.

5. Connecting cladding to the steel structural skeleton.

6. Application of a final coat of painting on top.

Issues in the erection process:

- The erector discovers the anchor bolts are placed wrongly.

- safety issues

- Erection or fabrication errors

- Faulty work of other trade contractors

- Erection equipment loads onto the structure

Hybrid construction :

Hybrid system is a combination of precast and other building systems used for other reasons. It uses both modular and pre-fabricated elements. The use of steel or any other metal increases the spanning capacity, strength, ease of construction, etc.

Advantages:

- Functionality and Versatility

- Efficiency and durability

- Reduced maintenance

- Mobility and user satisfaction.

Disadvantages:

- expensive

- Skilled workers required

- Rigid design and inflexible renovation

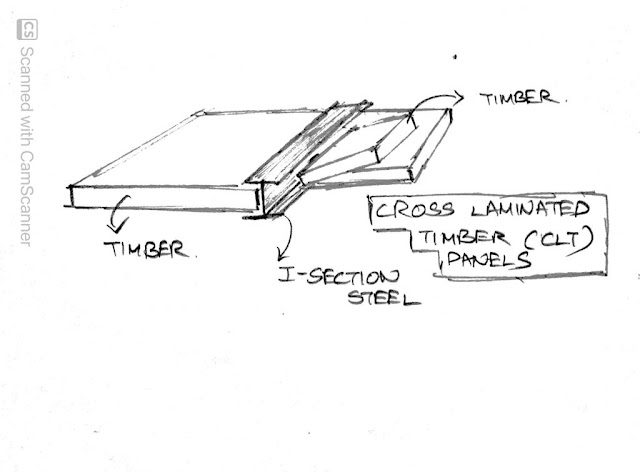

EXAMPLE -

|

| TIMBER- STEEL HYBRID CONSTRUCTION FOR MODERN MULTI-STOREY BUILDING |

REFERENCES:

http://abarsazeha.ir/images/ScinteficResources/Steeltips/SSEC_TIP_53.pdf

http://northern-weldarc.com/fabrication-erection-steel-structures/

https://www.steel.org.au/focus-areas/fabrication-and-erection/

http://www.steel-insdag.org/TeachingMaterial/chapter41.pdf

https://www.constrofacilitator.com/hybrid-building-design-and-its-advantages/

https://www.sheffield.ac.uk/civil/steel/project-folder/timber-steel-hybrid-construction

Signing off

Tejashri Kumaresan

Comments

Post a Comment